Your First Choice for Precision Manufacturing

At GEM Manufacturers, we pride ourselves on our world-class toolmaking and engineering department, complemented by cutting-edge facilities designed for high efficiency and precision. Our high-tech plastic injection molding facility, along with our automated tin and silver-plating surface treatment department, ensures that we can meet diverse manufacturing needs with excellence.

Our metal pressing facility features six German Bruderer High-Speed Metal Presses, capable of producing an impressive 1,200 components per minute (equating to 20 components per second!). This unmatched speed and efficiency make us the ideal partner for businesses seeking large-scale production with impeccable quality.

We are committed to customer satisfaction, renowned for our reliability, quality, and exceptional value. As a certified ISO 9001:2000 quality-based system plant, GEM Manufacturers is dedicated to maintaining the highest standards in every aspect of our operations.

Whether you need components made at scale and speed, with a guarantee of perfection, GEM Manufacturers should be your starting point.

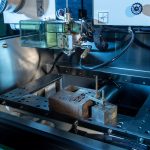

PLASTIC INJECTION

Injection moulding is a method to obtain moulded products by injecting plastic materials molten by heat into a mould, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing.

- Plastic injection machines with capacities ranging from 50T to 250T

- High-tech injection moulded components for the telecommunications industry

- Standard plastic injection moulding for a virtually unlimited number of applications

Get A Consultation With Experts

© GEM Manufacturing 2021 | Site desgined and maintained by Ovation Internet