Your First Choice for Precision Manufacturing

At GEM Manufacturers, we pride ourselves on our world-class toolmaking and engineering department, complemented by cutting-edge facilities designed for high efficiency and precision. Our high-tech plastic injection molding facility, along with our automated tin and silver-plating surface treatment department, ensures that we can meet diverse manufacturing needs with excellence.

Our metal pressing facility features six German Bruderer High-Speed Metal Presses, capable of producing an impressive 1,200 components per minute (equating to 20 components per second!). This unmatched speed and efficiency make us the ideal partner for businesses seeking large-scale production with impeccable quality.

We are committed to customer satisfaction, renowned for our reliability, quality, and exceptional value. As a certified ISO 9001:2000 quality-based system plant, GEM Manufacturers is dedicated to maintaining the highest standards in every aspect of our operations.

Whether you need components made at scale and speed, with a guarantee of perfection, GEM Manufacturers should be your starting point.

More details about our services:

TOOLMAKING

Conventional Milling

- Step into the world of machining milling, a dynamic process that utilizes rotary cutters to expertly remove material from a workpiece. With the ability to operate in multiple directions across various axes, milling ensures exceptional accuracy in shaping and cutting. This versatile technique covers everything from intricate parts to heavy-duty gang milling operations, making it a favorite in manufacturing. Renowned for producing custom components with exact tolerances, machining milling is your go-to solution for high-quality production. Whether you're crafting simple components or complex assemblies, machining milling empowers you to create with precision and confidence!

- Machining Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

CNC Milling

- milling is one of the most common processes when looking to produce complex parts or surfacing.

Milling Capabilities

- • Work Piece Size - 450 x 400 x 400 mm

- • Thread Cutting

- • Tapping

- • Complex Surfacing

- • Bore Roundness - 10µm

- • Positioning Accuracy - 10µm

EDM WIRE & EDM SPARK ERODING Electrical discharge machining

- Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage.

LATHE

- versatile machine tool designed to rotate a workpiece around a central axis, enabling various precision operations such as cutting, sanding, knurling, drilling, deformation, facing, threading, and turning. By applying specialized tools to the workpiece, the lathe crafts objects with perfect symmetry around the axis.versatile

SURFACE GRINDING

- Surface grinding is done on flat surfaces to produce a smooth finish. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or non metallic substance from a workpiece, making a face of it flat , sharp or smooth.

CYLINDRICAL GRINDER

- cylindrical grinder is a specialized form of grinder meant for work on cylinders, rods, and other similar workpieces. The cylinder rests between two centers and rotates in one direction, while the grinding wheel or wheels approach and rotate in the opposite direction. In this way, a cylindrical grinder works much like a lathe would, except ...

METAL PRESSING

- • Metal pressing of components up to 160 tons and high speed up to 1200 strokes per minute

- • Conventional metal pressing and forming for low to medium volumes

- • High speed metal pressing and forming for high volume requirements such as electrical contacts, cable connectors and small mechanical components

- • Pitch-feed, tonnage displacement, vacuum control to prevent slugs from lifting, frame barriers to control part injection and stroke counter to facilitate mist lubrication and strip cut-off each time a set number of strokes has been reached.

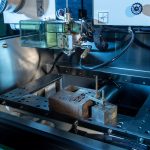

PLASTIC INJECTION

- Injection moulding is a method to obtain moulded products by injecting plastic materials molten by heat into a mould, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing.

- • Plastic injection machines with capacities ranging from 50T to 250T

- • High-tech injection moulded components for the telecommunications industry

- • Standard plastic injection moulding for a virtually unlimited number of applications

SURFACE TREATMENT

- Advanced Surface Treatment: Elevating Quality through Tin and Silver Plating At the forefront of precision manufacturing, our surface treatment processes enhance the durability and performance of your components. We specialize in automated tin plating and silver plating, providing superior protection against corrosion and ensuring optimal conductivity for electronic components. Our tin plating process offers excellent solderability and resistance to oxidation, making it ideal for a wide range of applications. Meanwhile, silver plating delivers exceptional electrical performance, making it a top choice for high-frequency and high-performance electronic devices. With our cutting-edge technology and commitment to quality, we ensure that every component meets rigorous industry standards. Experience the difference that advanced surface treatments can make in elevating the functionality and longevity of your products!

Get A Consultation With Experts

© GEM Manufacturing 2021 | Site desgined and maintained by Ovation Internet